The Ultimate Guide to Epoxy Pigments: Enhancing Your Resin Projects

Introduction to Epoxy Pigments

Epoxy pigments are specialized colorants designed to be used in epoxy resin applications, providing a wide range of colors and effects that can dramatically enhance the aesthetic appeal of various projects. These pigments are specifically formulated to disperse evenly, allowing for a uniform color distribution within the resin. They play a crucial role in transforming clear epoxy resin into vibrant, customized masterpieces, suited for artistic creations, industrial applications, and decorative objects.

The primary function of epoxy pigments is to impart color and depth to the resin. When mixed, they not only contribute to the visual aspect but also ensure that the color remains stable throughout the curing process. This stability is essential as it allows the final product to maintain its intended color over time, resisting fading due to exposure to UV light and environmental conditions. There are various types of epoxy pigments available, including liquid dyes, powdered pigments, and metallic pigments, each offering unique characteristics that cater to different artistic requirements.

Using pigments in epoxy resin opens up a world of creative possibilities. Artists and crafters can achieve stunning swirls, gradients, and even multi-layered effects by experimenting with different applications of these colorants. Additionally, the flexibility of epoxy pigments allows users to mix colors, create custom shades, and develop unique designs tailored to specific project needs. This versatility makes epoxy pigments an indispensable tool for hobbyists and professionals alike.

Moreover, the application of epoxy pigments extends beyond mere aesthetics. They can also enhance the opacity, transparency, and overall finish of the cured product, resulting in a more polished and professional appearance. With these benefits combined, it is clear that epoxy pigments are essential elements in the realm of resin applications, providing both beauty and functionality to a vast array of projects.

The Different Types of Epoxy Pigments

Epoxy pigments come in various forms, each with distinct characteristics and benefits tailored to a wide range of resin projects. The primary types include liquid pigments, powdered pigments, and paste pigments, each offering unique advantages depending on the desired outcome.

Liquid pigments are among the most popular options due to their ease of use and versatility. These pigments are pre-mixed with a carrier, allowing for smooth incorporation into the epoxy resin. Their fluid consistency ensures even distribution and minimizes clumping, resulting in vibrant colors throughout the project. Liquid pigments are particularly well-suited for projects requiring transparency or translucency, making them ideal for creating layered effects or ocean-themed designs. Additionally, they are available in a vast array of colors, giving users ample choice to match their artistic vision.

Powdered pigments offer a different approach, coming in dry form that users must measure and mix into the resin manually. These pigments can be used to achieve rich, opaque colors and often provide more depth than their liquid counterparts. When mixed properly, powdered pigments can produce a textured finish, making them popular for applications such as countertops, tables, or decorative art pieces. One advantage of powdered pigments is their long shelf life and concentrated nature, which means only a small amount is needed to achieve substantial color intensity.

Lastly, paste pigments combine the attributes of both liquid and powdered pigments. They have a thicker consistency, allowing for excellent color saturation while enabling precise application. Paste pigments can be used effectively for detailed work, including artistic designs and intricate patterns. Their versatility makes them suitable for a range of projects, including resin art, jewelry making, and even furniture refinishing. Each type of epoxy pigment caters to specific needs, ensuring that creative enthusiasts can find the right solution for their resin projects.

Choosing the Right Pigment for Your Project

Selecting the appropriate epoxy pigment for your specific resin project is a crucial step that can significantly impact the overall aesthetic and functionality of the finished product. One of the primary factors to consider is colorfastness. This property indicates how well the pigment will stand up to UV light exposure and the effects of time. Pigments with high colorfastness are particularly advisable for outdoor projects, as they are less likely to fade over time, keeping your creations vibrant and appealing.

Opacity is another vital factor in pigment selection. Depending on the effect you aim to achieve, you may require a pigment that offers full opacity, allowing for solid colors, or a translucent option that permits light to pass through, which can create stunning designs when layered. Be mindful of how the choice of opacity will influence the final appearance of your resin piece. If you are uncertain, consider testing a small batch to gauge opacity levels before committing to the larger project.

Compatibility with different resin types cannot be overlooked. Not all pigments work equally well with every epoxy resin. It is essential to check the manufacturer’s recommendations regarding the specific pigment you plan to use. Some pigments may react chemically with certain resin formulations, leading to undesirable results such as curing issues or discoloration. Researching and confirming compatibility will help you avoid these pitfalls.

Finally, consider the desired finish for your project. Whether you are aiming for a matte or glossy look can influence your pigment choice. Certain pigments enhance gloss in a resin mixture, while others may be more suited to a matte finish. By assessing these factors—colorfastness, opacity, compatibility, and finish—you can confidently select the right epoxy pigment that meets your project requirements and elevates your resin creations.

Mixing and Measuring Pigments for Optimal Results

When working with epoxy pigments in resin projects, achieving the desired color intensity and consistency requires careful measurement and mixing. The ratio of pigment to resin is crucial for optimal results. Generally, a good starting point is to use 5-10% pigment by weight compared to the total weight of the resin. This allows for vibrant coloration without compromising the resin’s integrity.

Using precise measuring tools, such as a digital scale, ensures accuracy in your measurements. Avoid using volumetric measurements like cups, as they can lead to inconsistencies. Instead, weighing the components will help maintain the quality and performance of your epoxy. It is also advisable to conduct small test batches before committing to larger projects. This way, you can adjust the pigment concentration based on the desired effect and achieve better outcomes.

Once the pigment is measured correctly, the next step is to mix it into the resin. To ensure even color distribution, it is recommended to pour the pigment into the resin rather than the other way around. Gently stir the mixture with a clean stir stick or a suitable mixing tool for at least two minutes, paying attention to the edges and bottom of the mixing container where pigmentation can settle. Be careful not to introduce air bubbles during this process, as they can detract from the finished appearance.

Additionally, consider the type of epoxy pigment used, as some pigments may be more concentrated than others. For instance, liquid pigments might require less material compared to powder forms. Following the manufacturer’s guidelines for dilution ratios can enhance mixing efficiency and color performance. By adhering to these best practices, you can ensure that your epoxy projects achieve uniform color distribution, elevating the overall aesthetic and quality of your creations.

Tips for Achieving Unique Effects with Epoxy Pigments

Epoxy pigments offer a versatile medium for artists and DIY enthusiasts interested in creating unique effects in their resin projects. By manipulating the pigments creatively, one can achieve stunning visuals that enhance the overall quality of the artwork. This section outlines various techniques to experiment with epoxy pigments, focusing on layering, marbling, and creating shimmering finishes.

One of the most effective techniques is layering. By allowing each layer of resin to partially cure before adding the next layer of colored epoxy, you can create depth and complexity in your artwork. It is essential to choose contrasting colors for each layer to make the effects more pronounced. Clear resin can also serve as a base layer, providing an elegant backdrop that accentuates the colors used in subsequent layers.

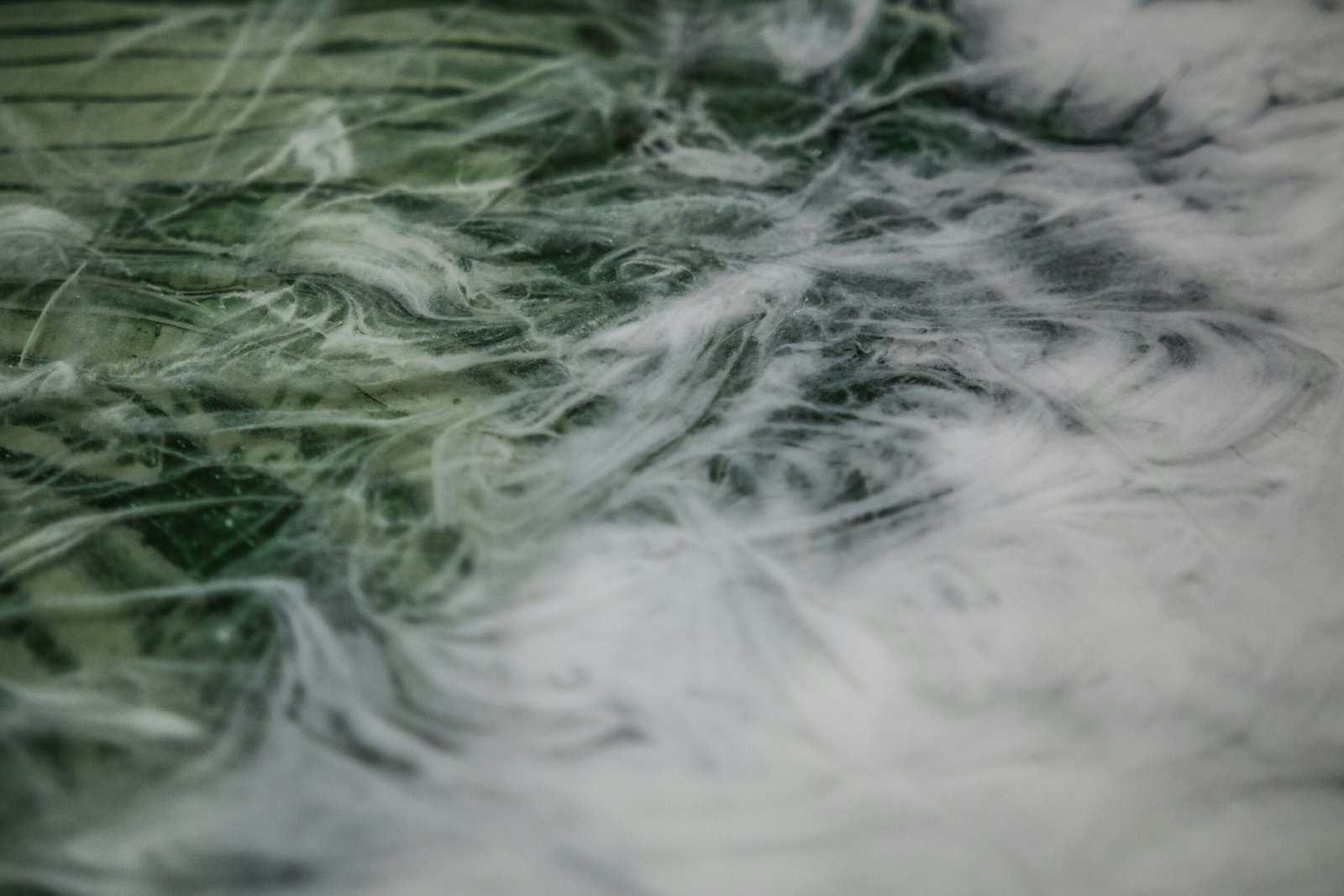

Another exciting technique is marbling. This can be achieved by using a combination of colors and manipulating them with tools such as a toothpick or a palette knife. By swirling the colors together, you can create unique patterns that resemble natural marble, adding sophistication to your projects. To enhance the marbling effect, consider using a heat gun to slightly warm the resin, allowing the pigments to blend more fluidly.

For those seeking a shimmering finish, the addition of metallic or pearlescent epoxy pigments can deliver eye-catching results. When mixed into the resin, these pigments catch the light, creating an alluring glow. It is advisable to experiment with different concentrations to achieve the desired effect, ensuring that neither the resin nor the pigments overpowers each other. Applying a final layer of clear resin over the finished piece can also seal in the shimmer while adding a glossy finish.

Ultimately, experimentation is key to unlocking the full potential of epoxy pigments. By practicing these techniques, artists can develop their unique styles and enhance their resin projects with captivating effects.

Safety Precautions When Working with Epoxy Pigments

Engaging with epoxy pigments and resins necessitates a conscious approach to safety. Given that some components can release harmful fumes or create skin irritations, well-defined precautions should always be at the forefront of any project. The first and fundamental step is the use of appropriate personal protective equipment (PPE). Essential items include gloves, safety goggles, and a respirator mask. These protect against potential skin contact, eye exposure, and inhalation of harmful vapors emitted during mixing and curing.

In addition to PPE, ensuring adequate ventilation is crucial. Working in an area with poor airflow can lead to the accumulation of toxic fumes, raising health risks. It is advisable to work outdoors or in a well-ventilated space. Utilizing exhaust fans or opening windows can significantly diminish the concentration of these vapors. If necessary, a filtered respirator is an ideal addition to the safety arsenal, particularly for individuals sensitive to chemical odours.

Moreover, maintaining a clean and organized workspace plays a vital role in safety. Epoxy pigment spills can lead to slip hazards or unintended contamination of surfaces. Regularly cleaning any spillage and properly disposing of waste materials can help mitigate these risks. Additionally, labeling all chemicals and adenosine can aid in identifying potential hazards quickly, should any accidents occur.

Before initiating any resin project, reading the safety data sheet (SDS) for both epoxy pigments and resins is essential. This document provides critical information about hazards, handling instructions, and first-aid measures. By being informed and prepared, individuals can enjoy the creative process associated with epoxy pigments while minimizing health risks. Ultimately, prioritizing safety ensures a more pleasant and productive workspace, enabling artisans to focus on their craft with peace of mind.

Common Challenges and Solutions in Using Epoxy Pigments

Working with epoxy pigments can present several challenges that may arise during the application process. One of the most frequent issues encountered is pigment settling. This occurs when the pigments do not remain evenly distributed throughout the epoxy mixture, leading to a less vibrant color result. To combat this, it is essential to thoroughly mix the epoxy and pigments together, ensuring an even consistency. Additionally, allowing the mixture to sit for a short period before pouring can facilitate better dispersion of the pigments.

Another common challenge is color fading after curing. Epoxy pigments, particularly those that are not UV resistant, may lose their vibrancy when exposed to sunlight over time. To mitigate this risk, it is advisable to select high-quality pigments specifically marketed as UV resistant. Incorporating a UV stabilizer into the resin mixture can also help protect the pigments from degradation caused by prolonged sun exposure.

Clarity of the finish is a further concern, as many users aim for a crystal-clear result in their resin projects. Inadequately mixed pigments can lead to a cloudy appearance in the finished product. Using transparent epoxy resins specifically designed for clarity can help eliminate this issue. A gentle mixing technique is also recommended, as vigorous stirring can introduce bubbles that affect the overall appearance. Allowing the mixture to rest before pouring can help any bubbles to rise to the surface and pop, resulting in a more professional finish.

In conclusion, awareness of these challenges and their solutions is essential for achieving successful outcomes with epoxy pigments. By taking proactive measures and employing suitable techniques, one can significantly enhance the quality and aesthetic appeal of resin projects.

Inspiration: Showcasing Stunning Epoxy Pigment Projects

Epoxy pigments have revolutionized the world of resin art, allowing creators to explore a myriad of colors and finishes in their projects. The versatility of these pigments makes them suitable for various applications, inspiring artists and hobbyists alike to experiment and innovate. This section presents a selection of stunning epoxy pigment projects that highlight the aesthetic and functional possibilities of resin art.

One noteworthy application is in the realm of furniture design. Many artisans have begun incorporating epoxy pigments into tabletops and countertops, transforming ordinary wooden surfaces into dazzling statement pieces. The use of swirling colors combined with transparent layers of resin creates a mesmerizing effect, resembling a beautiful ocean or abstract galaxy. These pieces not only serve practical purposes but also function as eye-catching art that enhances any space.

Another inspiring area is the creation of decorative art pieces, such as sculptures and wall art. Artists using epoxy pigments can achieve intricate patterns and vibrant color blends that evoke emotion and capture attention. From abstract designs to floral representations, these projects showcase the limitless possibilities offered by epoxy pigments. Many artists share their techniques and processes online, which encourages others to pick up resin art as a new hobby.

Moreover, epoxy pigments are finding their way into functional items like coasters, jewelry, and accessories. Creators are infusing everyday objects with a touch of color, transforming them into bespoke items that reflect individual style. Epoxy-pigmented coasters, for instance, not only serve as practical home items but also function as conversation starters in gatherings, displaying unique craftsmanship.

By exploring these various applications, one can appreciate how epoxy pigments elevate both artistic expression and functional design. Whether in furniture, art, or everyday items, the integration of these pigments opens up a world of creativity, inviting all to make their own resin masterpieces.

Where to Buy Quality Epoxy Pigments

When it comes to selecting high-quality epoxy pigments for resin projects, the availability of reliable suppliers is crucial. Many consumers often question where to purchase these pigments, considering factors such as pigment quality, authenticity, and brand reputation. A variety of sources can provide exceptional options, including local craft stores, specialty suppliers, and reputable online platforms.

Local craft stores and hardware stores often carry a selection of epoxy pigments. While they may not possess the vast variety available online, these locations allow buyers to observe the product firsthand. Retail staff can also offer helpful advice on which pigments work best for specific resin applications, enhancing the overall purchasing experience.

For a more diverse selection, specialty resin suppliers should be considered. These retailers typically focus exclusively on resin and related products, ensuring that they offer only quality epoxy pigments. Certain brands, such as Alumilite, ArtResin, and Smooth-On, are well-known within the crafting community for their highly pigmented and durable products. Investigating these brands can provide confidence in the quality of the pigments being purchased.

Online shopping has become a flexible and convenient option for acquiring epoxy pigments. Numerous e-commerce platforms and craft-focused websites provide extensive catalogs and detailed reviews. Websites like Amazon, Etsy, and dedicated resin art suppliers often feature customer testimonials, which can provide insight into the pigments’ performance.

As you consider different suppliers, it is essential to evaluate the quality of pigments. Look for information regarding the pigment’s opacity, lightfastness, and mixing capabilities. Authenticity can also be a concern; thus, purchasing from established brands or manufacturers ensures that the pigments meet high standards. Assessing the seller’s reputation through reviews and ratings will further assist in making an informed decision, ultimately ensuring your resin projects achieve the desired aesthetic and quality.